extrunet tool systems ensure product and process stability

extrunet systems meet the requirements of modern profile extrusion for extrusion tools in all areas

- Quick-change systems for die and calibre

- State-of-the-art active water management

- Targeted influencing of the profile geometry during operation

Change your extrusion tool now! Save time now!

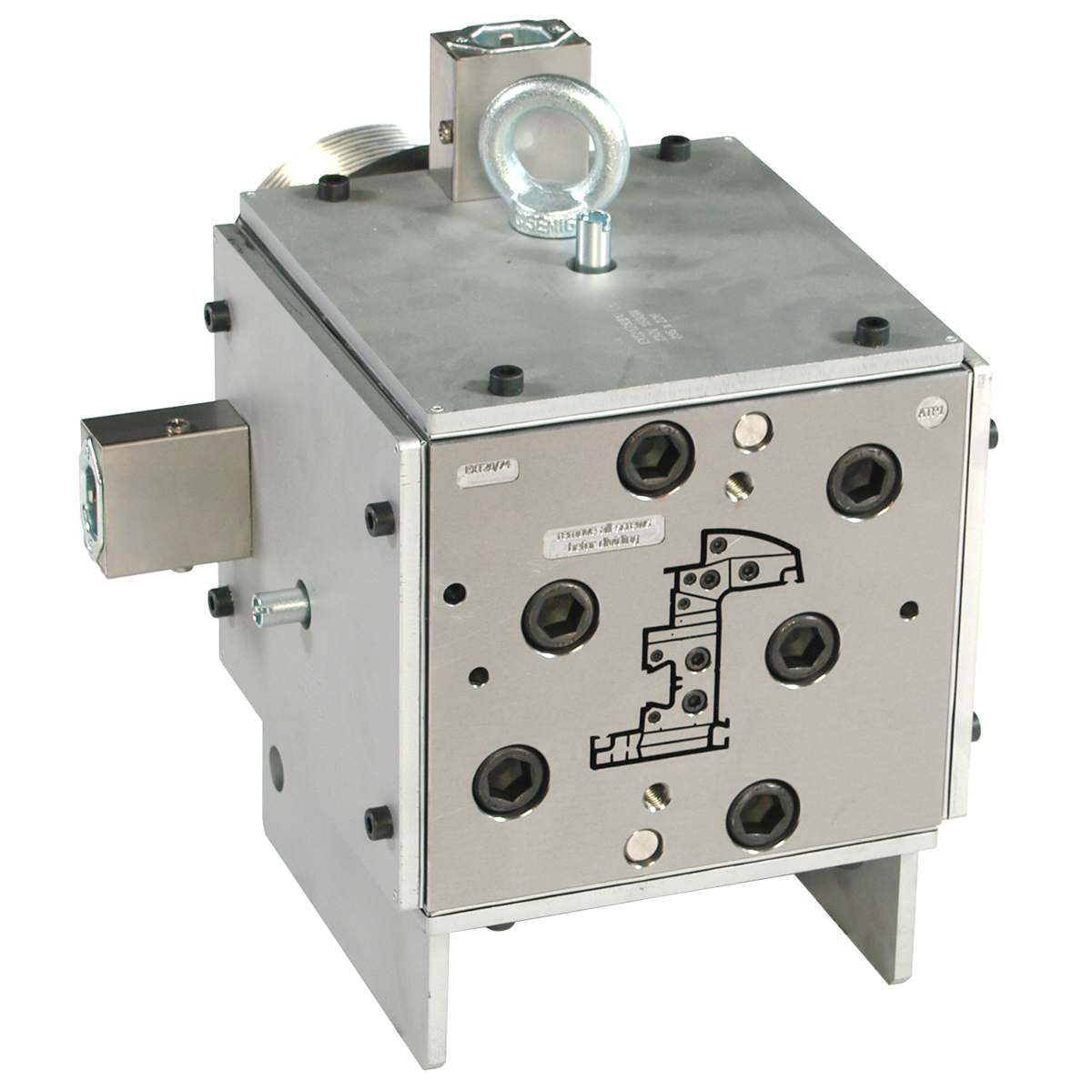

extrunet die systems

Productivity through short set-up times and high process stability

- Quick-change system with die hinge

- Quick-change system with round die insert (ideal for co-extrusion)

- Rectangular die

- Foam die

- Influence the profile geometry by sectional cooling of the profile (e:MAC)

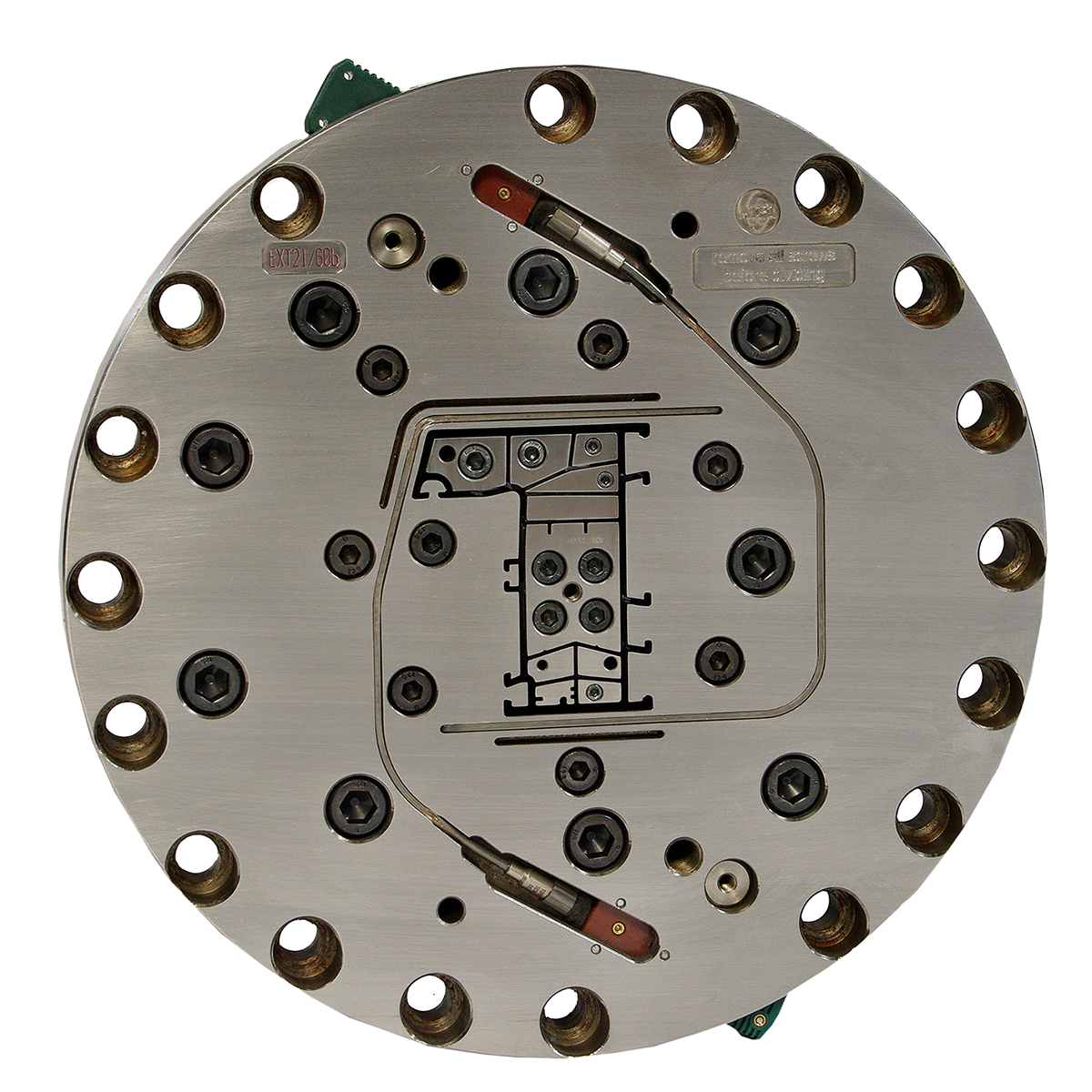

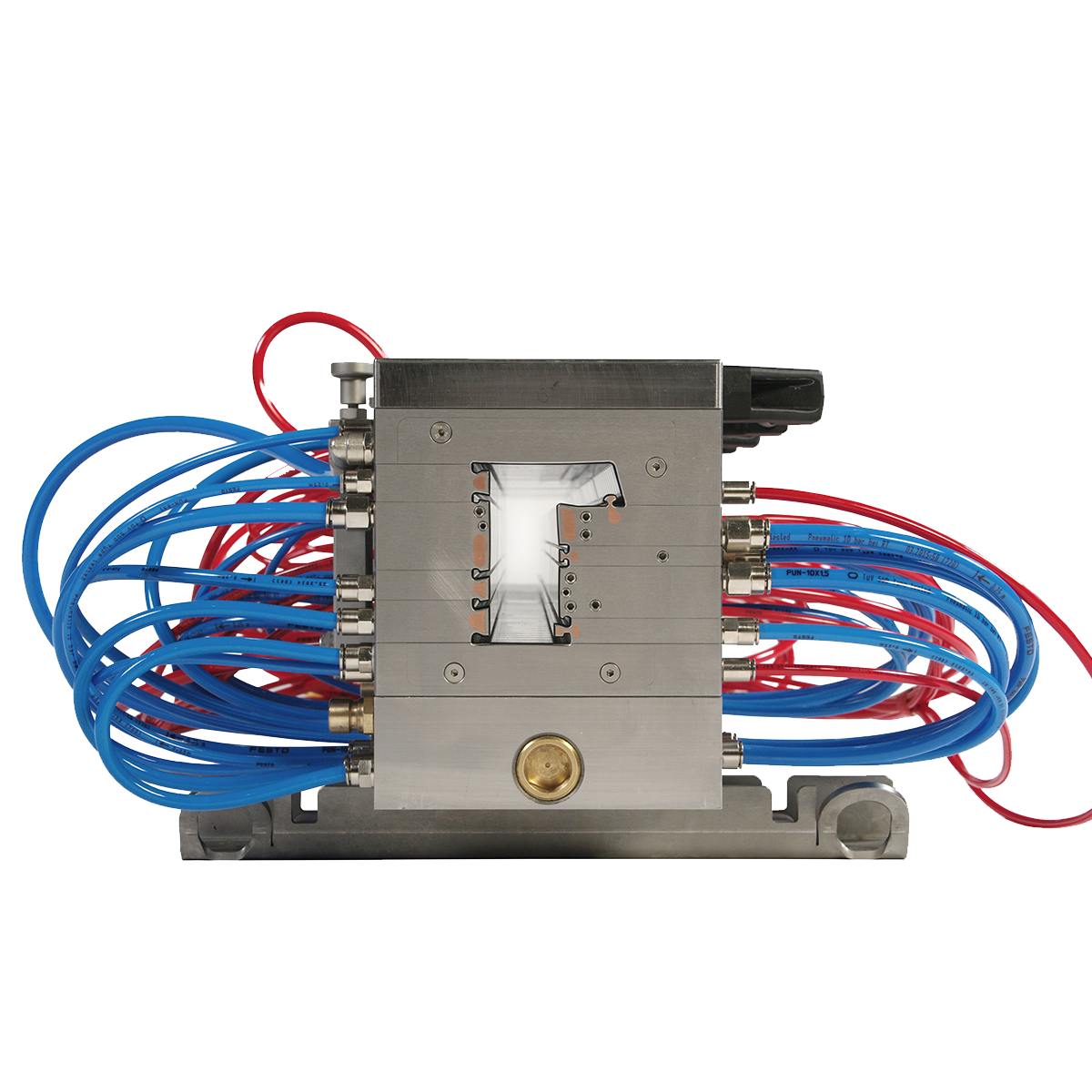

extrunet calibration systems

Tooling change without the use of tools

Depending on the application, calibre blocks of different lengths (up to 280mm) are used.

- Dry caliber systems up to 6 blocks

- Quick-change system with media supply from below

- Calibration systems in the tank

- Influence on profile geometry by sectional cooling of the profile (e:MCC)

extrunet Tank systems

Vacuum tank / spray tank / water tank

Optimal support of the calibration through the use of

- Vacuum tanks

- Spray tanks

- Water bath

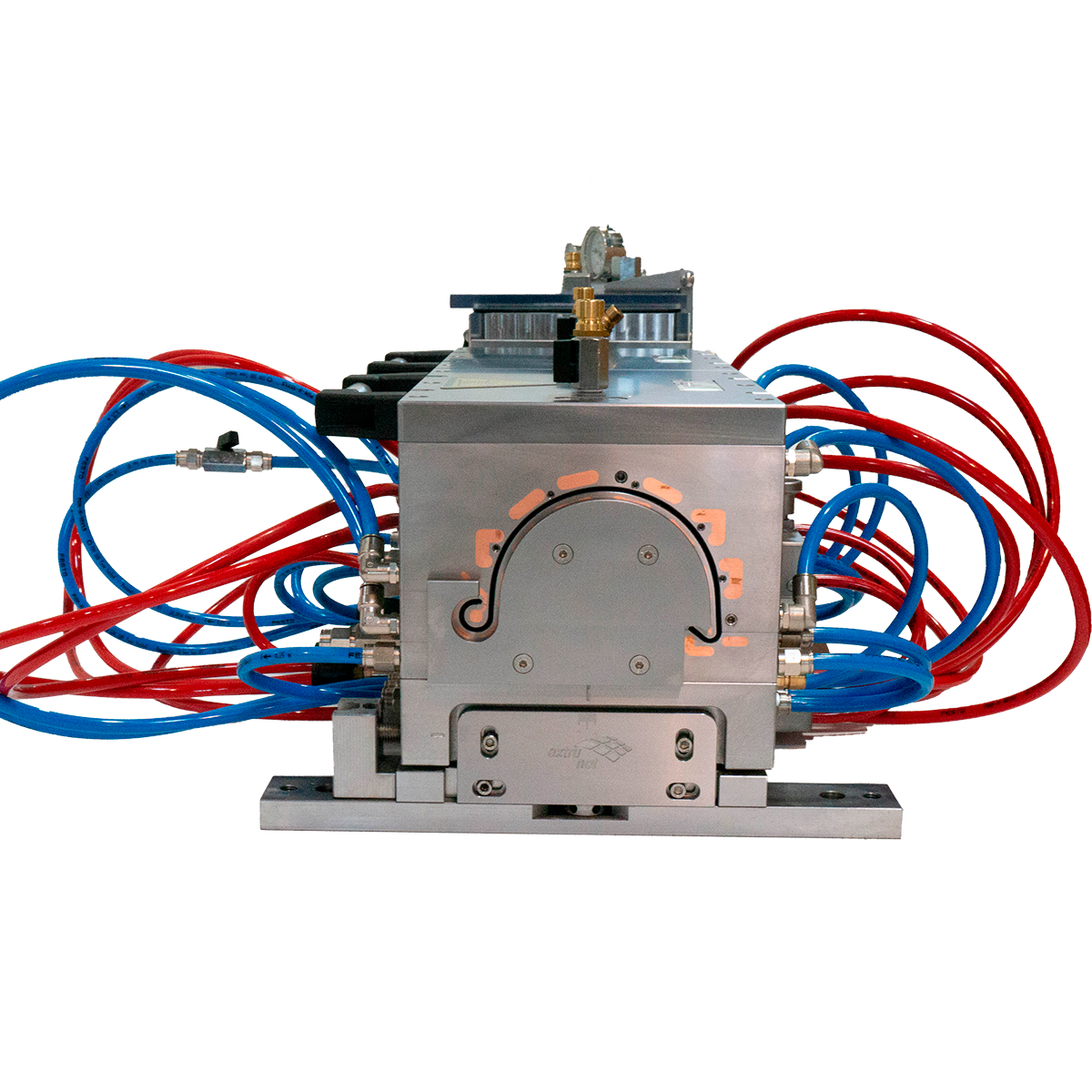

extrunet POST CO Extrusion

for soft PVC seals

Soft PVC seals can be extruded in a post co-extrusion process. With the help of this system, the gasket can be pressed on during the production of the main profile.

Can be used together with our Co-Extruders.